Marya Pharmaceutical Liquid Injection Glass Bottle Vial Filling Machine for Liquid Filling Sealing Production Line

Overview Package Size 180.00cm * 100.00cm * 150.00cm Package Gross Weight 1200.000kg Marya Pharmaceutical Liquid Injecti

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Certification | CE, GMP, ISO |

| Voltage | 220V |

| Computerized | Computerized |

| Customized | Customized |

| Condition | New |

| Warranty | 1 Year |

| After-sales Service | Field Installation, Commissioning and Training |

| Transport Package | Standard Export Package |

| Specification | Standard/Customized |

| Trademark | Marya |

| Origin | China |

| Production Capacity | 10000PCS/Month |

Packaging & Delivery

Package Size 180.00cm * 100.00cm * 150.00cm Package Gross Weight 1200.000kgProduct Description

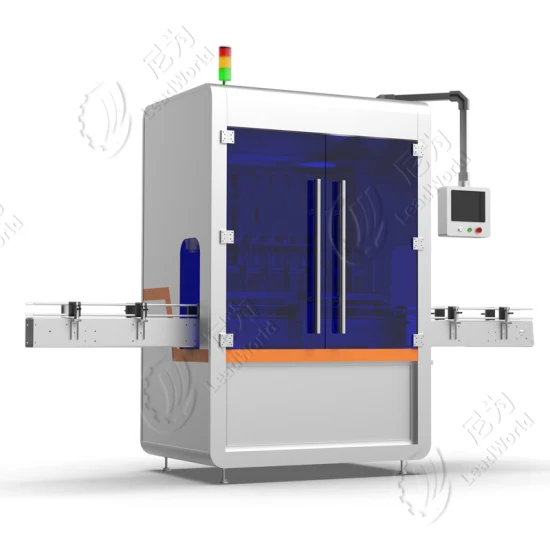

Marya Pharmaceutical Liquid Injection Glass Bottle Vial Filling Machine for Liquid Filling Sealing Production Line

Product Description

Introduction :

The pharmaceutical vial filling production line is mainly used for washing, sterilizing, filling and sealing injection vials ranging from 1-30ml in pharmaceutical industries under aseptic conditions. The vial washing filling stoppering capping line consists of ultrasonic washing machine, hot air circulation drying sterilization tunnel, filling stoppering machine, and capping machine, each machine can be used in combination or in single.

Performance Features

- The vial liquid filliing production machine meets new GMP requirements, and the cleaning effect meets the new Pharmacopoeia standards and requirements.

- The via liquid filling production machine can adopt straight-line layout or wall-to-wall L-shaped layout to reduce risk of cross-contamination and ensure aseptic level.

- Applicable specification: 1ml-100ml vial (as per user's requirement)

- Production Capacity: 1000-36000BPH

- Number of filling head: 1-20, to be selected according to the output

- Filling Accuracy: ≤ ±1% (according to drug characteristics)

- Choice of various filling pumps: glass pump, metal pump, peristaltic pump, ceramic pump;

- Capping qualified rate: ≥99.9%

- Compact and simple structure, occupies less area;

- Stable product performance, easy and reliable operation, beautiful appearance;

- High degree of automation, few operators required;

- Single row or double row filling;

- Optional real-time display and printing system of sterilization temperature;

- The heat in the hot air circulation tunnel oven is evenly distributed, and the heat resources removal effect is good.

- Optional online sterilization function for the cooling section of hot air circulation tunnel oven.

- Optional open-RABS isolation protection system and class 100 laminar flow hood protection;

- Optional high-performance no-bottle-no-filling, no bottle no stoppering, no bottle no capping and squeeze stop functions;

- The vial filling capping machine can be equipped with dust exhaust device, which can absorb aluminum scraps produced during capping and thus reduce the risk of environmental pollution.

- The whole line can be equipped with online monitoring system to monitor key factors that affect product quality (such as dust particles, planktonic bacteria, wind speed, wind pressure, etc.).

- Full-line linkage control function;

- To realize fully automatic control and monitor of production process, high precision colored touch screen operation monitoring, PLC automatic control & automatic protection, main machine frequency conversion speed regulation and other control technology are used.

- Applicable for wide range of bottle specifications, and easy to replace mould.

- The products can be customized according to customer's actual demand.

| Model | KGF4 | KGF6 | KGF8 | KGF10 | KGF12 | KGF20 | KGF24 |

| Applicable specifications | 2~30ml vial bottles | ||||||

| Filling heads | 4 | 6 | 8 | 10 | 12 | 20 | 24 |

| Production capacity | 50-100bts/min | 80-150bts/min | 100-200bts/min | 150-300bts/min | 200-400bts/min | 250-500bts/min | 300-600bts/min |

| Stoppling qualification rate | >=99% | ||||||

| Laminar air cleanliness | 100 grade | ||||||

| Vacuum pumping speed | 10m3/h | 30m3/h | 50m3/h | 60m3/h | 60m3/h | 100m3/h | 120m3/h |

| Power consumption | 5kw | ||||||

| Power supply | 380V 50Hz | ||||||

About Us

Workshop

Certificate

Project case

Our Customer

Exhibition & Our Team

Packaging & Shipping

Related Products

-

![Chocolate Sauce Salad Dressing Honey Mayonnaise Chili Sauce Mushroom Sauce Juice Drink Ketchup Canned Tomato Paste Canning Line Filling Machine]()

Chocolate Sauce Salad Dressing Honey Mayonnaise Chili Sauce Mushroom Sauce Juice Drink Ketchup Canned Tomato Paste Canning Line Filling Machine

-

![High Speed Vertical Rice Bag Dog Food Chemical Fertilizer Sealer Fr1100]()

High Speed Vertical Rice Bag Dog Food Chemical Fertilizer Sealer Fr1100

-

![Vffs Granular/Soy/Sauce/Vinegar/Oil/Coffee/Honey/Powder/Paste/Seasoning/Sugar Packin Sachet Strip Pouch Automatic Sealing Filling Food Packing Packaging Machine]()

Vffs Granular/Soy/Sauce/Vinegar/Oil/Coffee/Honey/Powder/Paste/Seasoning/Sugar Packin Sachet Strip Pouch Automatic Sealing Filling Food Packing Packaging Machine

-

![2022 Hot Table Top Vacuum Packing Machine Shrink Packing Machine]()

2022 Hot Table Top Vacuum Packing Machine Shrink Packing Machine