Fully Automatic Multihead Weigher Canning Weighing Food Multi

Overview Package Size 2400.00cm * 2370.00cm * 3050.00cm Package Gross Weight 1579.000kg Product Features 1. Fully automa

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | JW-B24 |

| Application | Dairy Products, Vegetable, Fruit, Fish, Meat, Snack, Rice, Flour, Food |

| Type | Filling and Sealing Machine |

| Forming Species | Bag Moulding |

| Forming Function | Forming, Filling, Seal |

| Driven Type | Electric |

| Material Type | Grain |

| Packaging | Bag |

| Packaging Material | Plastic |

| Packaging Accuracy | 0.5-20g |

| Packaging Capacity | 100-1000g |

| Packaging Speed | 70 Bags/Min |

| System Output | 250set/Year |

| Transport Package | Wooden Crate Package |

| Specification | Stainless Steel |

| Trademark | Kenwei |

| Origin | Guangdong, China |

| Production Capacity | 250 Set /Year |

Packaging & Delivery

Package Size 2400.00cm * 2370.00cm * 3050.00cm Package Gross Weight 1579.000kgProduct Description

Product Features

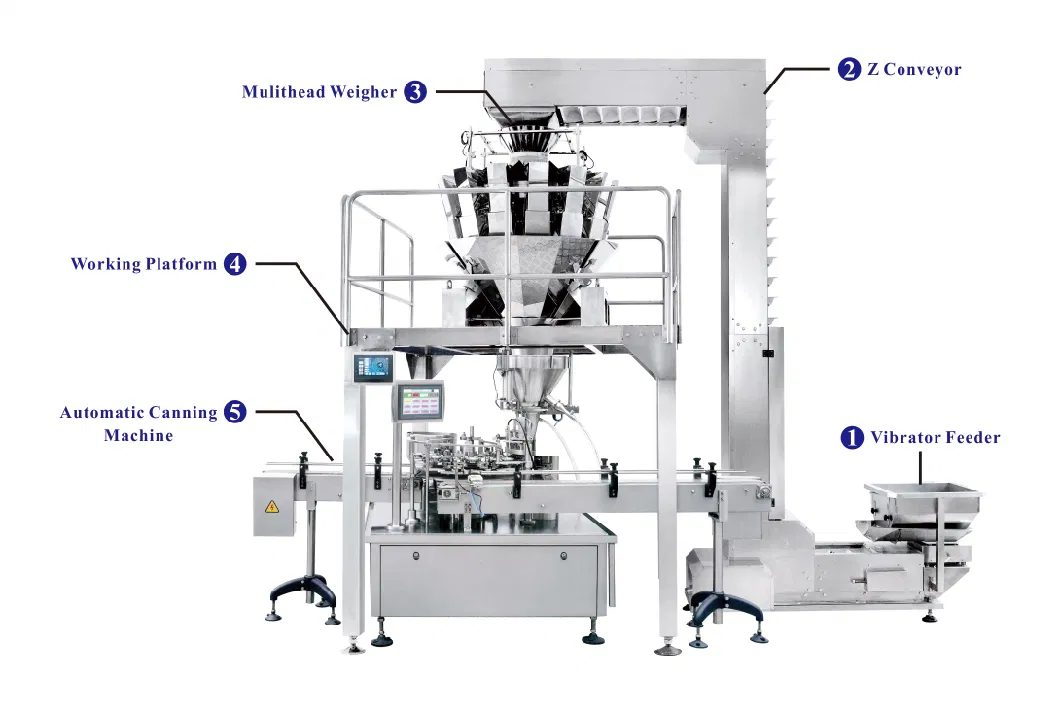

1. Fully automatic finishing the whole process of feeding, weighing, filling, date printing, and labeling.2. High accuracy, Double Outlet efficiency increased by about 1 time.3. Applicable to a wide range of materials.4. It is suitable for weighing snack foods such as candy, melon seeds, jelly, frozen, pistachio, peanuts, nuts, almonds, raisins, etc, and is suitable for puffed food; hardware, plastic compounds, and other granular, flaky, strip, round and irregular shape material.

Tank Type:

Product Parameters

| Series model | Typical Machine | Speed | Max weight |

| Single jar canning system | 10 head multihead weigher | 40p/min | 1000g |

| One divides into two canning system | 14 head multihead weigher | 70p/min | 800g |

| Check weigherReject unqualified products, it can sort the product and make statistics (if already equipped with other weight detection equipment then no need to use this machine) |

| Horizontal metal detector:It is used to detect the metal which mixed during the production process. It is suitable to use after finishing packaging (if already equipped with other metal detectors then no need use this machine). |

| Dropped metal detector:It is used to detect the metal which mixed during the production process. It is suitable to use before packaging.It is installed between weigher and packaging machine,space saving (if already equipped with other metal detector then no need use this machine). |

| Metal detector combined with check weigher:It is used to detect the metal and check weight, combined the check weigher with a metal detector, save cost and less commissioning and maintenance time. |

| Stuffing machine:It is used to stuffing the small bag into the cup, like desiccant, the flavoring bag, etc. |

| Electromagnetism induction aluminum foil sealing machine:Encapsulate the bottleneck with aluminum foil, mainly used in high sealing requirements of packaging, and usually work with stuffing machines. |

| Labeller:The label on the cup, the form of label including unilateral label, bilateral label, etc. |

Factory Photos

Certifications

Exhibition

Service

Pre-sale InquiryWe will help you customize an appropriate weighing and packing solution based on your requirements and specific circumstances.Installation ServiceWe will send professional technicians for on-site installation and commissioning upon request.Maintenance ServiceKenwei provides long term maintenance service, and maintenance parts are free within the warranty period and only charge parts expensed if your warranty has expired.Employee TrainingKenwei offers free technical training for our clients to fully master correct product maintenance techniques.Custom ServiceKenwei designs custom production lines for our clients according to specific weighing and packing products,output,packing styles,factory area and other factors.Company Profile

Guangdong Kenwei Intellectualized Machinery Co.,Ltd. is currently a large production base of multihead weighers. As a professional manufacturer, we devote to R&D and manufacturing of multihead weighers, linear weighers, check weighers, metal detectors with high speed and high accuracy. We also provide customers with complete automatic weighing and packaging systems to meet the various customized requirements.Kenwei, located in Hi-tech Industrial Zone, owns modern workshop over 21000 square meterwith annual production capacity of more than 5,000 sets of multihead weigher . We have a high-quality team that professional technicians more than 30% with comprehensive capacity from design and development, manufacturing, marketing, installation and commissioning, technical training,after-sales services and providing automatic weighing packaging system customization.With the development of international markets, more and more marketing and service networks are established all over the world. We won trusts and good reputations for good and fast services, which also help us to establish good brand image in the packaging machinery industry We are now selling machines to more than 80 countries in the world.

FAQ

Q1: How to know which packing machine is suitable for us?You can first tell the business representative which equipment you want to know, what material is the product,

how many grams to weigh, and the range of accuracy and speed

requirements. Our engineers then recommend suitable

packaging machines based on these data and product characteristics.

Q2: How to operate it?

Many languages are available for global markets. There are not only detailed instructions but also machine

videos for reference learning.

Q3: Why we should choose your company?

We have many years of industrial production and management experience, professional R & D, sales, after-sales

team. It can perfectly solve all the problems that customers

encounter from purchase to sale.

Q4: How to cooperate with you?

You only need to contact our business representative, and they will be patient to guide you through the whole

process.

Q5: What's your payment way?

T/T by our bank account directly.

Q6: How about the delivery and after-sales service?

All our machines are tailor-made because different clients have different requirements, delivery will be within

20 days for the small multihead weigher, For the large-scale

machine, it takes longer.

Q7:Warranty?

2 years (Electric accessories) and free lifetime maintenance.

Related Products

-

![Kunba SMT]()

Kunba SMT

-

![Full Automatic Tomato Paste Hot Sauce Honey Jar Ketchup Filling Machine]()

Full Automatic Tomato Paste Hot Sauce Honey Jar Ketchup Filling Machine

-

![Chocolate Sauce Salad Dressing Honey Mayonnaise Chili Sauce Mushroom Sauce Juice Drink Ketchup Canned Tomato Paste Canning Line Filling Machine]()

Chocolate Sauce Salad Dressing Honey Mayonnaise Chili Sauce Mushroom Sauce Juice Drink Ketchup Canned Tomato Paste Canning Line Filling Machine

-

![Vacuum Sealer/Single Chamber Vacuum Sealing Machine /Vegetable vacuum Packing Machine]()

Vacuum Sealer/Single Chamber Vacuum Sealing Machine /Vegetable vacuum Packing Machine